Company Profile

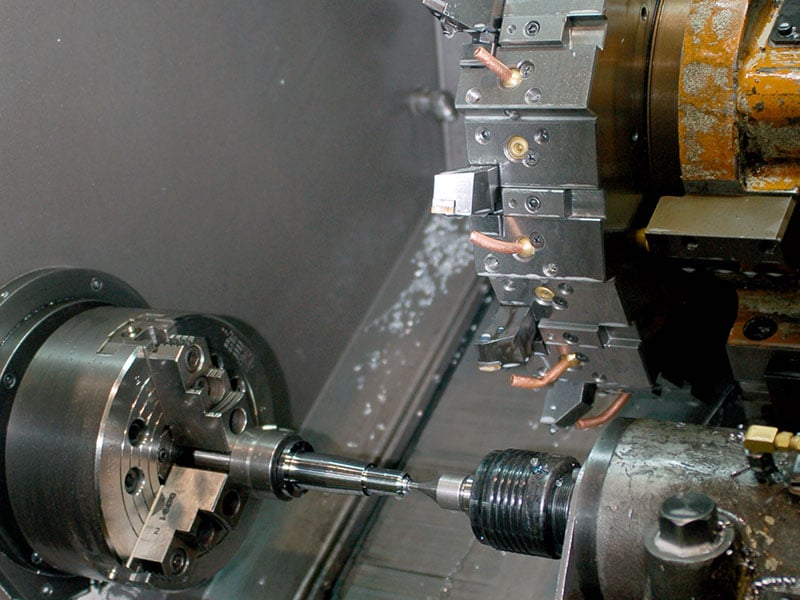

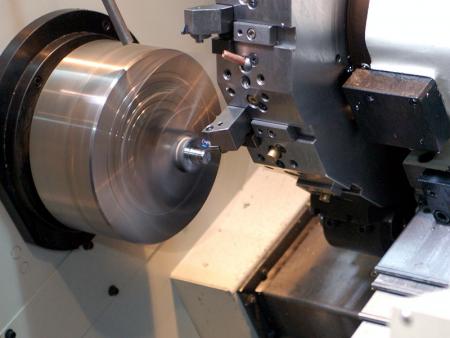

CNC Machining Expert, especially in suspension and steering parts.

Great Auto Parts: Over 30 Years of Excellence in Automotive Parts

Great Auto Parts has over 30 years of experience in producing high quality and durable car parts, such as rack ends, tie rod ends, ball joints, stabilizer links, control arms, bushings, and numerous other chassis parts used in automobile steering and suspension systems. We are proud to be IATF 16949:2016 certified,which ensures that our products are manufactured to the highest standards of quality and reliability. Choose us for excellent car parts that you can rely on.

With a technical and manufacturing team that engages in large volume production of mature auto chassis parts products, it is necessary to maintain rigorous step - by - step processes, and first - class production equipment, along with a certified professional technical staff. In order to gain complete control over production and its related manufacturing costs, we are vertically integrated from receipt of raw material to final shipment of the product. This includes forging, sand blasting, CNC machining, shot peening, ball burnishing, thread rolling, assembly, and all related in process and final assembly testing and packaging. In order to further shorten our delivery schedules and involve product traceability, we have introduced large-scale robotic arms and Smart Factory Management 4.0, to improve our productivity and lead times.

Tailored Solutions for Global Demands

We focus on producing customer design products (ODM / OEM). Small quantities and special design machining parts are very welcome. Our main customers are world leading aftermarket manufacturers worldwide.

Innovation for a Sustainable Future

In 2022, our venture into sustainability and innovation led to the establishment of a specialized assembly line for heavy commercial vehicle components. This expansion enriched our product offerings with adjustable control arms tailored for off-road vehicles, bus steering drag links, and bespoke steering tie rod ends designed for agricultural machinery. Advancing towards 2024, our commitment to environmental stewardship is further exemplified by our pledge to achieve net-zero carbon emissions, affirming our dedication to sustainable manufacturing practices and the well-being of our planet.

Videos

Discover Great Auto Parts: Quality, Innovation, Reliability

We are focusing on manufacturing vehicle high performance ball studs over 30 years. With all most every processes are in house, We provide not only the quality you expected but also the traceable products you need. As we continue to evolve and advocate for sustainable practices, we invite you to join us in shaping the future of automotive excellence.

For partnerships, inquiries, or more information about our suspension parts and beyond, connect with us via Whatsapp at +886-910-581280 today.