Research & Design

Reflecting on our years in the automotive sector, it's clear that our commitment to robust Research & Design has been the key to our enduring success. Nestled within the bustling halls of our company, the R&D department is a hive of innovation—where ideas morph into breakthroughs that redefine what cars can do. Our assembly products are developed from OEM samples, and follow the American standards SAE J490, J491; as well as the German automotive aftermarket quality standards and specs. Currently the models developed include, European, American, Japanese and Korean cars with the ranges up to 2500 items and 150 more parts developed every year.

Why R&D Matters to Us

Over the years, we've channeled over 3% of our annual turnover into R&D to not only enhance the existing product lines but to ensure our new developments meet and exceed evolving market demands and customer expectations. This substantial investment in R&D has enabled us to continuously improve the physical properties and process characteristics of our products, resulting in high-quality advancements that our customers trust. We fully understand it is our responsibility to ourselves and our customers' to continuously seek ways to reduce product costs though adopting innovative ways to increase productivity, developing efficient processing methods, reducing raw materials costs, improving overall work methods and the elimination of scrap, wherever we find it.

Our Annual R&D Budget

Our R&D budget reflects our unwavering commitment to innovation, enabling us to stay ahead of industry trends and continuously enhance the quality and functionality of our products.

Investing in Future Technologies

Allocating more than 3% of our yearly turnover, we focus on pioneering new technologies and enhancing existing ones. This investment fuels our ability to not only keep pace with industry advancements but to define them, ensuring that we deliver the most advanced and reliable products on the market.

Comprehensive Product Testing Services

Our comprehensive product testing services are designed to meticulously assess the safety and effectiveness of our automotive components. By rigorously evaluating each product's performance, safety, and durability, we ensure that our offerings meet the highest industry standards and consistently exceed customer expectations.

Ensuring Product Safety and Efficiency

Our extensive product testing services are structured to rigorously assess the safety and functionality of our products. Through advanced testing techniques, we make certain that each product not only meets but frequently surpasses the requisite safety standards.

Impact Testing: Our Rigorous Approach

Impact testing is integral to our product validation protocol. This testing confirms that our products can endure extreme conditions and usage scenarios, providing assurance of their reliability and durability.

Pull-Off Testing: Certifying Durability

Pull-off testing is a key element of our quality assurance strategy. It evaluates the adhesive strength of coatings and materials in our products, which is vital for verifying their longevity and resilience.

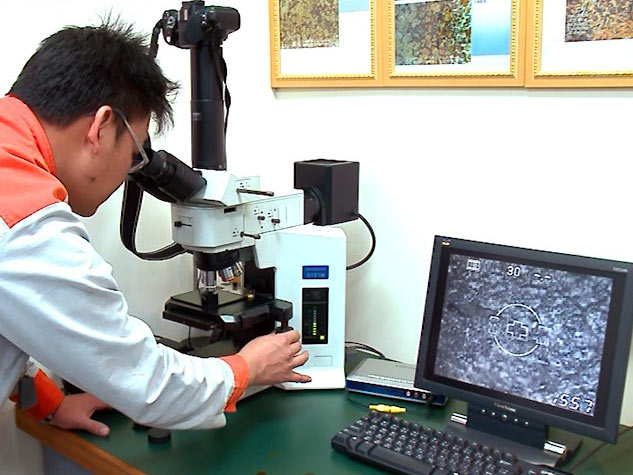

Material Metallurgical Microscope Research

Our commitment to excellence extends to the microscopic examination of our materials. Employing state-of-the-art metallurgical microscopes, we thoroughly assess the internal structure and integrity of our materials, ensuring each product batch adheres to our stringent quality standards.

Expertise in Automotive Parts Manufacturing

Our extensive experience in automotive parts manufacturing drives our ability to innovate and maintain industry leadership, shaping our approach from design to delivery.

30 Years of Industry Leadership

With three decades of experience in automotive parts manufacturing, we have not only positioned ourselves as industry leaders but have also deepened our understanding of market demands. This longstanding presence has equipped us with invaluable insights that enhance our R&D and design processes.

From Concept to Road: Our Journey

Each automotive part we develop starts with a concept designed to address specific customer needs or market gaps. Our process from concept to road involves multiple phases of design refinement, thorough testing, and integration of customer feedback, ensuring that the final product performs flawlessly.

Professional Advice and Planning

We provide expert advice and process planning tailored to each customer’s specific requirements. Our team collaborates closely with clients to convert their needs into practical, effective solutions.

Custom Process Planning for Your Needs

Recognizing the unique challenges and requirements of each client, we specialize in bespoke process planning. This tailored approach allows us to design and implement manufacturing processes that are perfectly aligned with the specific needs of our clients, maximizing efficiency and product quality.

ESG and Corporate Sustainability

Our dedication to Environmental, Social, and Governance (ESG) principles is integrated into every aspect of our operations, reflecting our commitment to sustainable and ethical practices across the board. By integrating environmental stewardship, social responsibility, and strong governance, we aim to achieve sustainable growth that benefits our stakeholders, the community, and the environment.

Environmental Stewardship

Our commitment to the environment is embedded in every aspect of our operations. We actively pursue reductions in our environmental footprint through several strategic initiatives:

- Resource Efficiency: We continuously improve our manufacturing processes to increase efficiency and reduce waste. This involves optimizing our use of materials and energy throughout our production cycles, ensuring that we not only comply with environmental regulations but also exceed them.

- Sustainable Materials: We are dedicated to adopting more sustainable and recyclable materials in our product designs and manufacturing processes. This commitment not only helps reduce the ecological impact of our products but also caters to the growing consumer demand for environmentally friendly products.

- Innovation in Product Design: Our R&D department plays a crucial role in enhancing the environmental performance of our products. By focusing on developing products that are not only effective but also eco-friendly, we ensure that innovation aligns with sustainability goals.

Videos

GAP is proud to present you with brand new publicity film in 2023. We are focusing on manufacturing vehicle high performance ball studs over 30 years. With all most every processes are in house, We provide not only the quality you expected but also the traceable products you need. Let us be your reliable business partner. Contact us now, Whatsapp +886-910-581280 for more details.