How Do Tie Rod Ends Play An Important Role In A Car?

What is a Tie Rod End

A tie rod end is an important component of the car's control system, commonly found in most four-wheeled vehicles. Each front wheel of a car requires an inner tie rod end and an outer tie rod end to connect the steering knuckle and rack end. When you turn the steering wheel, the tie rods push and pull the front wheels, making your car turn in the desired direction.

What Do Tie Rods Do for a Car

Tie rods play a crucial role in the vehicle's steering and suspension systems. They connect the steering gear to the steering knuckle, enabling the transmission of force from the steering wheel to the wheels, which allows the vehicle to turn. By maintaining the alignment of the front wheels, tie rods help ensure that the car drives straight and handles well. Properly functioning tie rods are essential for maintaining precise steering control, preventing uneven tire wear, and ensuring overall vehicle safety.

How Tie Rod Ends Contribute to Vehicle Safety

Tie rod ends not only help maintain the alignment of your wheels but also absorb some of the shocks and vibrations from the road, contributing to a smoother ride. If tie rod ends fail, steering responsiveness is compromised, leading to potential safety hazards like unpredictable steering behavior or even loss of control over the vehicle.

Are Tie Rods Part of Suspension

Tie rods are integral components of both the steering and suspension systems. While they primarily belong to the steering system, their role in connecting the steering gear to the steering knuckle also impacts the suspension system. The steering system includes parts like the steering wheel, steering column, steering gear, inner and outer tie rods, and the steering knuckle. The suspension system comprises components such as springs, shock absorbers, struts, control arms, and ball joints. Together, the steering and suspension parts work harmoniously to ensure vehicle stability, smooth handling, and comfort by managing road shocks, maintaining tire contact with the road, and enabling precise steering control.

Why are Steering Tie Rod End Important

Steering tie rod ends are crucial components of a vehicle's steering system that connect the steering rack or center link to the steering knuckle. Typically located at the outer ends of the steering rack or center link, tie rod ends are attached to the steering knuckle using ball and socket joints. We essentially serve as the pivot point between the steering system and the wheels, facilitating the transmission of steering input from the driver to the wheels. In simple terms, without tie rods, you cannot control a car.

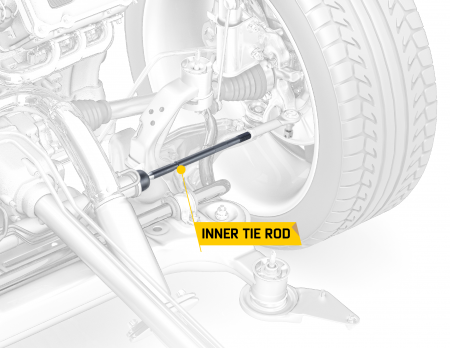

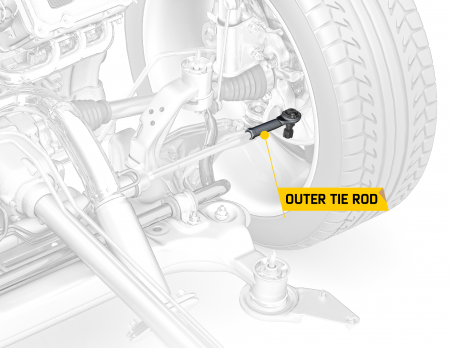

What is Different Between Inner And Outer Tie Rod End

Steering rod ends consist of two main parts: the inner tie ord (rack end) and outer tie rod (tie rod end). The inner tie rod end connects to the steering gear, while the outer tie rod end connects to the steering knuckle. These two parts work together to ensure that when you turn the steering wheel, your car's wheels respond accurately.

The inner tie rod end is typically located inside the steering mechanism and is less exposed to external elements, which often means it has a longer lifespan. The outer tie rod end, on the other hand, is connected near the wheel and is more vulnerable to wear and tear due to exposure to road conditions and debris.

While primarily part of the steering system, steering rod ends also have a crucial role in the vehicle's suspension system. They help maintain proper wheel alignment, ensuring that the wheels are pointing in the correct direction at all times. This alignment is vital for even tire wear, proper vehicle handling, and overall driving comfort.

Comparison of Inner and Outer Tie Rods

| Feature | Inner Tie Rod | Outer Tie Rod |

| Location | Inside steering mechanism | Next to the wheel |

| Function | Transfers steering force to steering linkage | Transfers steering force to wheel steering linkage |

| Positional Requirements | Must be located inside steering mechanism | Installed near the wheel within the steering mechanism |

| Responsible Operation | Converts steering wheel input to wheel direction | Controls vehicle steering |

| Installation Information | Requires installation within steering mechanism | Requires installation near the wheel |

| Safety | Affects vehicle handling and safety | |

How Long Do Steering Tie Rod Ends Last

The lifespan of tie rod ends can vary widely depending on several factors, including the type of vehicle, driving conditions, and maintenance practices. While there isn’t a universally fixed mileage for when tie rod ends should be replaced, understanding the factors that influence their durability can help you determine when it might be time to inspect or replace them.

Driving Conditions

- Urban vs. Rural: Tie rod ends tend to last longer in vehicles primarily driven in urban areas with smooth, paved roads. Conversely, vehicles frequently driven on rough or unpaved roads, such as in rural or off-road conditions, may experience faster wear on their tie rod ends due to the increased stress and impact.

- Weather and Road Conditions: Harsh weather conditions, like extreme cold or excessive heat, and exposure to road salt or chemicals can accelerate the wear of tie rod ends. Salt, in particular, can lead to corrosion, which weakens the tie rod ends and reduces their lifespan.

Vehicle Type and Usage

- Heavy-Duty Vehicles: Larger vehicles, such as trucks or SUVs, which carry heavier loads, often put more stress on tie rod ends, leading to faster wear compared to smaller, lighter vehicles like sedans.

- High-Mileage Vehicles: Vehicles that are driven extensively, especially for long-distance commuting or commercial purposes, will naturally experience more wear and tear on their tie rod ends.

Quality of Tie Rod Ends

The quality of the tie rod ends themselves is a significant factor. Original Equipment Manufacturer (OEM) parts are generally designed to meet specific standards for durability and performance. High-quality aftermarket tie rod ends can also offer good longevity, especially if they meet or exceed OEM specifications. However, cheaper, low-quality parts may not last as long.

While it’s difficult to specify an exact mileage, tie rod ends typically last between 50,000 to 100,000 miles under normal driving conditions. However, this range can vary widely depending on the factors mentioned above. Regular inspection of tie rod ends, especially after 50,000 miles, is recommended to ensure they are in good condition and to prevent unexpected failures.

Enhancing Safety with Heat-Treated Ball Studs for Inner and Outer Tie Rods

To enhance the safety of Inner and Outer Tie Rods, heat-treated ball studs play a pivotal role. This treatment improves the rods' strength, wear resistance, and structural stability, reducing the risk of failures and ensuring the reliability of the steering system. Moreover, in the event of impact, heat-treated ball studs can bend without fracturing, absorbing some of the force and potentially preventing more severe damage to the steering components. By increasing the durability of steering components, we effectively mitigate uncertainties in vehicle handling, thus elevating driving safety.

What Is Heat Treatment and Why Do We Use It

Heat treatment is a process used to enhance the physical and mechanical properties of metals, such as hardness, strength, and wear resistance. In the context of automotive components, heat treatment involves heating the metal to a specific temperature and then cooling it rapidly or slowly, depending on the desired outcome. The process alters the microstructure of the metal, making it significantly tougher and more resistant to stress and deformation.

Benefits of Heat-Treated Ball Studs in Tie Rod Ends

- Increased Strength and Durability: Heat-treated ball studs are much stronger, allowing tie rod ends to endure greater forces without bending or breaking, ensuring longer lifespan and reliable performance.

- Improved Wear Resistance: The hardened surface of heat-treated ball studs reduces wear from friction, prolonging the life of tie rod ends, especially in demanding driving conditions.

- Enhanced Structural Stability: Heat-treated ball studs maintain their integrity under extreme conditions, helping to prevent tie rod end failures that could lead to loss of steering control.

- Resistance to Fracturing: Heat treatment increases toughness, making ball studs more likely to bend than break under severe impact, reducing the risk of complete steering failure.

Incorporating heat-treated ball studs into the design of inner and outer tie rod ends is a crucial step in enhancing vehicle safety and performance. By increasing the strength, wear resistance, and structural stability of the ball studs, this process ensures that the tie rod ends can handle the demands of modern driving conditions, from everyday commutes to challenging road environments. The result is a more durable, reliable, and safe steering system that provides peace of mind to drivers.

Symptoms of a Bad Tie Rod

A failing tie rod, particularly the inner one, can disrupt a car's steering and handling. Symptoms include:

Uneven Tire Wear

A worn tie rod affects alignment, leading to irregular tire wear patterns.Unresponsive Steering

Excessive free-play between the tie rod and the steering knuckle results in less precise steering.Vibration in the Steering Wheel

A damaged tie rod can cause noticeable vibrations, especially during driving or braking.Squealing or Clunking Noises

Worn tie rods may produce squeaking or clunking sounds, particularly during turns or over bumps.

Conclusion

Understanding the importance of tie rods and identifying early signs of wear can prevent steering issues and ensure your vehicle remains safe to drive. Regular maintenance and timely replacement of damaged tie rods are essential for optimal performance and safety.