What Are the Advantages of an Adjustable Sway Bar?

Understanding the Role of a Adjustable Sway Bar in Vehicle Stability

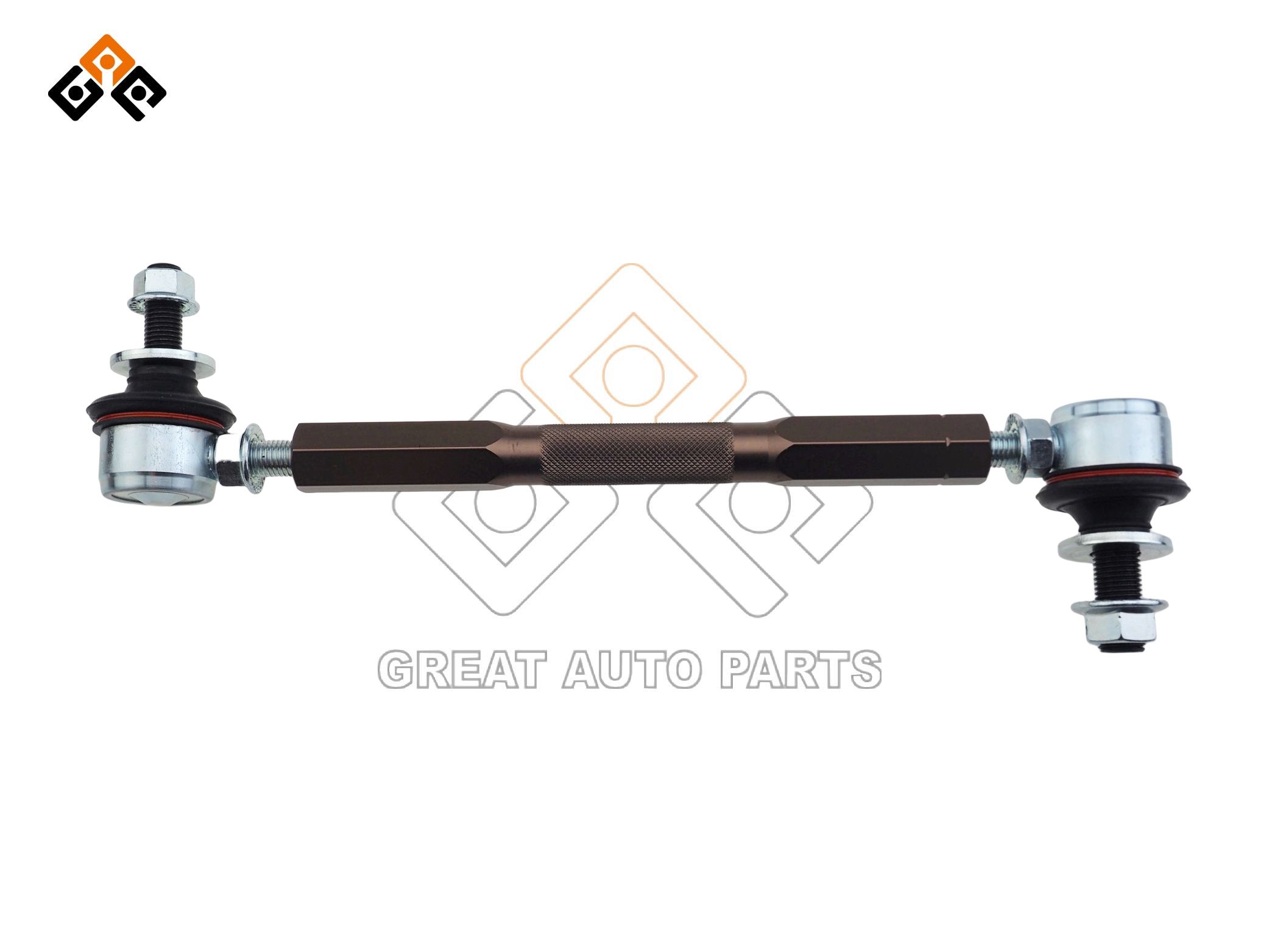

An adjustable sway bar, or known as adjustable stabilizer links, plays a pivotal role in reducing the body roll of a vehicle during fast cornering or over road irregularities. It connects opposite wheels together through short lever arms linked by a torsion spring, providing adjustable resistance to body roll.This adjustability allows for fine-tuning the balance of the car, catering to different driving styles and conditions, which is not always possible with standard sway bars.

The Difference Between Adjustable Sway Bars and Non-Adjustable Sway Bars

| Category | Adjustable Sway Bars | Non-Adjustable Sway Bars |

| Adaptability to Driving Conditions | Allows drivers to modify stiffness based on driving conditions, load, and personal preference. Offers a softer setting for comfort or stiffening for high performance. | Fixed in performance characteristics, offering no flexibility to adjust handling dynamics post-installation. |

| Performance Enhancement | Enhances vehicle balance and handling through fine-tuning, especially useful in racing or heavy-duty hauling. | Improves handling and reduces body roll but lacks optimization for different scenarios, limiting effectiveness in specialized applications. |

| Weight and Material Considerations | Designed with high-strength materials for durability and adjustability. Weight varies by design but focuses on long-term performance. | Hollow and tubular sway bars are lighter, improving fuel efficiency but offering less rigidity. Solid sway bars are heavier but provide strong, durable performance. |

| Installation and Maintenance | Similar installation to other sway bars but allows ongoing tuning without replacement, offering long-term versatility and lower maintenance costs. | Requires no adjustment after installation but lacks flexibility for changing conditions. Replacement may be needed to alter vehicle handling. |

| Cost-Effectiveness | More expensive upfront but offers long-term value through adaptability to different conditions, reducing the need for multiple or frequent replacements. | Cheaper initially but may not provide long-term value if different conditions or preferences require a sway bar with different performance characteristics. |

| Handling and Stability | Can be adjusted to optimize handling and stability for specific conditions, enhancing both performance and safety. | Provides consistent handling improvement but may be less effective in varying scenarios compared to adjustable options. |

What Are the Benefits of Using an Adjustable Sway Bar in Performance Vehicles

Adjusting a sway bar can significantly impact a vehicle's handling and performance. Here are the key effects:

- Reduction in Body Roll: Sway bars, also known as anti-roll bars, reduce body roll during cornering by distributing weight more evenly across the vehicle's tires. This enhances the tire contact patch on the road, leading to improved grip during cornering.

- Handling Dynamics: Adjusting the sway bar can influence the car's tendency to understeer or oversteer. For instance, stiffening the front sway bar can increase understeer, while stiffening the rear sway bar can increase oversteer.

- Cornering Speed: Proper sway bar adjustment allows for faster cornering by optimizing the car's handling in corners. This is particularly beneficial in performance driving and racing scenarios.

- Ride Comfort and Stability: A well-adjusted sway bar can make the ride smoother and improve stability, especially during high-speed maneuvers. It also helps in extending tire life and maintaining proper alignment.

- Overall Performance: By reducing body roll and improving grip, sway bars contribute to better overall vehicle performance, making the car more predictable and easier to control during aggressive driving.

How Adjustable Sway Bars Influence Understeer and Oversteer in Performance Vehicles

Adjustable sway bars play a significant role in tuning the balance between understeer and oversteer in performance vehicles. Here's how they affect this balance:

Front Sway Bar Adjustment:

- Stiffer Front Sway Bar: Increasing the stiffness of the front sway bar generally increases understeer. This is because a stiffer front sway bar reduces the front suspension's ability to roll, causing the front tires to lose grip sooner in a turn.

- Softer Front Sway Bar: Decreasing the stiffness of the front sway bar can reduce understeer, allowing the front tires to maintain better contact with the road and improving front-end grip

Rear Sway Bar Adjustment:

- Stiffer Rear Sway Bar: Increasing the stiffness of the rear sway bar generally increases oversteer. A stiffer rear sway bar reduces the rear suspension's ability to roll, causing the rear tires to lose grip sooner in a turn.

- Softer Rear Sway Bar: Decreasing the stiffness of the rear sway bar can reduce oversteer, allowing the rear tires to maintain better contact with the road and improving rear-end grip.

Balancing Act:

- Fine-Tuning: Adjustable sway bars allow for fine-tuning of the vehicle's handling characteristics. By adjusting the stiffness of both the front and rear sway bars, drivers can achieve a desired balance between understeer and oversteer. This is particularly useful in performance and racing applications where precise handling is crucial.

What Specific Adjustments Can Be Made to Sway Bars to Fine-Tune a Vehicle's Handling

Adjustable sway bars allow for several specific adjustments to fine-tune a vehicle's handling:

- Stiffness Adjustment: The primary adjustment involves changing the stiffness of the sway bar. This can be done by altering the position of the end links on the sway bar. Moving the end links closer to the bar's center increases stiffness, while moving them outward decreases stiffness. This adjustment helps in balancing understeer and oversteer.

- End Link Length: Adjusting the length of the end links can also fine-tune the sway bar's effectiveness. Shorter end links can make the sway bar more effective, while longer end links can reduce its impact. This adjustment can help in achieving the desired handling characteristics.

- Preload Adjustment: Preloading the sway bar involves adjusting the end links to apply a slight twist to the bar even when the vehicle is at rest. This can help in fine-tuning the handling balance and improving responsiveness during initial turn-in.

- Bar Diameter and Material: While not an on-the-fly adjustment, choosing sway bars of different diameters and materials can significantly impact handling. Thicker bars or those made from stiffer materials will provide more resistance to body roll, while thinner or more flexible bars will allow more roll.

Adjustable Sway Bar Usage Across Different Vehicle Types

| Vehicle Category | Purpose | Benefits |

| Cars | Reduce body roll during cornering, enhancing stability and handling. | Fine-tuning suspension setup to match driving conditions or personal preferences, improving dynamics. |

| Trucks | Manage higher center of gravity and heavier loads, reducing body roll and improving stability. | Adjustable stiffness to suit varying loads, enhancing safety and handling. |

| SUVs | Reduce body roll and improve stability, especially with a higher center of gravity. | Improve handling on-road while maintaining comfort, with options for sway bar disconnects for off-road. |

| Off-Road Vehicles | Can be disconnected to allow for greater axle articulation on rough terrain. | Increased suspension travel and traction, improving off-road performance by conforming to uneven surfaces. |

| Racing Vehicles | Fine-tune handling characteristics to suit specific tracks and driving styles. | Precise adjustments to balance and cornering behavior, critical for optimal track performance. |

Enhance Stability and Performance with Great Auto Parts Custom Adjustable Stabilizer Links

Take your vehicle's performance to the next level with our custom-made adjustable sway/stabilizer bar links, designed for maximum durability and precision. Whether you want to improve handling, reduce body roll, or adapt to various driving conditions, our expert team can craft the perfect solution to optimize your vehicle's stability and performance. Let us help you achieve a smoother, more responsive driving experience with ourcustomized stabilizer links.